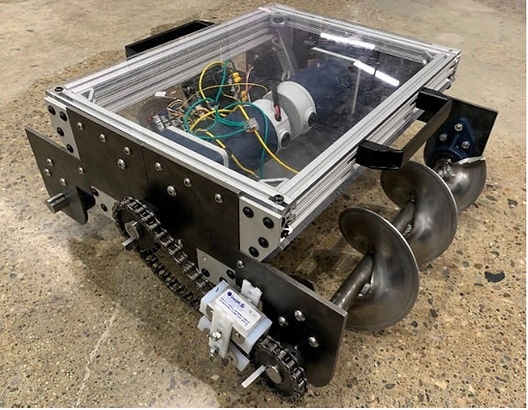

Little Exploration Rover (LER)

Over the last 60 years, over $20 billion has been spent on Mars exploration. Although many missions achieved success, no rover has ever traversed the red planet’s icy polar regions. Further, the typical Mars rover program costs more than $2.5 billion, rendering them a high-risk asset that must be operated with the utmost level of caution. As such, our team of mechanical engineering students assembled around the concept of a smaller, relatively inexpensive rover, capable of traversing the diverse terrains of Mars. Our proposed solution includes a compact, cost-effective rover that employs a unique screw propulsion mechanism designed to traverse the steep slopes of Mars. The screw propulsion mechanism enables minimal sinking and large propulsive forces on sand and loose rock, and the capacity to carve into ice to generate significant tractive forces on otherwise unnavigable polar ice slopes. Given the ease with which these vehicles navigate loose substrates, we shifted our focus to validating our design on ice. Through research, we discovered equations describing the capabilities of helical screws to propel a vehicle on ice, but their full detail was obscured. As such, we built a prototype with the aim of discovering these capabilities ourselves. At the time of this writing, the team has demonstrated the propulsive ability of the drive system on a flat ice surface. During testing on a sandy substrate, our prototype encountered a component-level failure that halted any further testing. Further testing was anticipated to demonstrate the prototype’s ability to climb sand at its 35-degree angle of repose, and ice at slopes up to 45 degrees. In the future, members of the team hope to pursue these goals in the form of a research project at Northeastern. Taking it a step further, we aspire for this concept to be adopted as a method of propulsion in future rovers by the global space exploration community.

LER Rover Initial Test at Matthew's Arena

Throughout the development of the Little Exploration Rover (LER), I utilized a diverse set of engineering skills. Our work required proficiency in CAD modeling to design the rover’s chassis and drivetrain, ensuring that the structure was stable and optimized for steep slopes. I applied Finite Element Analysis (FEA) in SolidWorks to evaluate the stresses and displacements in critical components, which helped us identify and address potential failure points. Additionally, hands-on fabrication skills were essential submitting jobs to the machine shop and assembled components like the screw-propulsion system and drivetrain. Testing on ice and sand allowed us to refine our troubleshooting and iterative design processes, teaching us how to quickly adapt when faced with unforeseen failures, such as the axle pin shearing during sand trials. Beyond technical skills, I learned the importance of collaboration, effective communication, and balancing design constraints with functionality. These lessons not only improved our prototype but also prepared me for future challenges in engineering design and research.

There is a lot to add here... Feel free to contact me if you'd like an update on the status of the project! Four members of the team (including myself) will be continuing the project as research during the Spring 2025 semester.